How To Build Your Own Cnc Wood Router

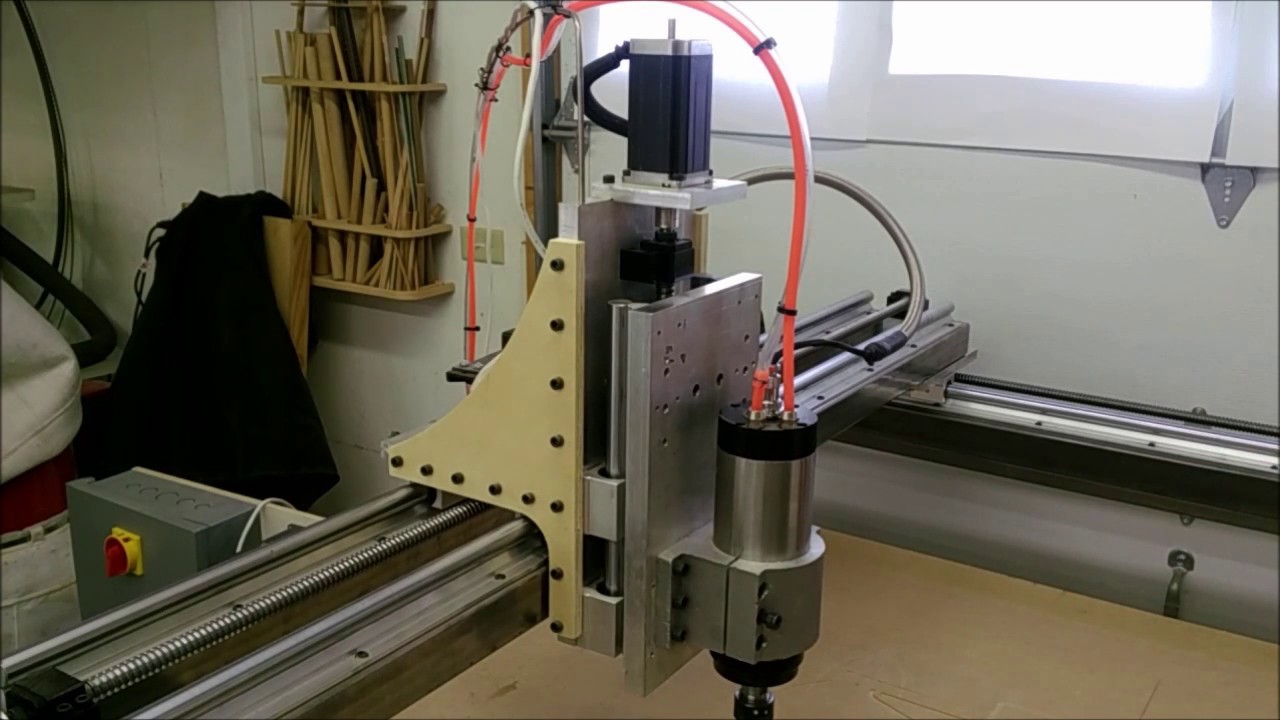

This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

How to build your own cnc wood router. But Ray built the moving-gantry CNC. 71 Start by attaching one of the timing belt pulleys to the front shaft of the. To make a bearing out of plastic just drill a hole the same diameter as the corresponding shaft.

And its a lot of bang for your buck. To provide additional support for the X-axis he set two pieces of tube steel into notches in the front and back of the machine. CNC wood router can make many instruments like piano guitar violin and others.

Nevertheless the key steps to build your own CNC machine will generally be as follows. The mechanical parts he had to. This project is ideal for tech-savvy woodworkers looking to add a CNC router.

This is my favorite step as it uses the fewest and most basic fabricated components is simple to complete and gives you a sense of achievement without doing a whole lot. Shipping cost will be provided when parts are ready to be shipped. The exact assembly of your CNC machine will depend on the type of machine you choose to build the custom options you choose what you plan on making with the machine and many other factors.

He also made a few sweet upgrades. A compact router baltic birch plywood some basic hardware and an off-the-shelf electronics kit are all you need to build your own computer-controlled router. A CNC machine is probably the most useful tool a hobbyist can own but the price for a CNC machine on the market is way more than the average hobbyist is willing to spend.

Depending on the difficulty level of your CNC machine you will need to invest in a spectrum of tools such as a band saw drill press laser cutter and a few hand tools. Assembled Option includes the complete CNC Router andor Laser is. This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it.