What Are The Different Types Of Marking And Measuring Tools Used In Fitting Shop

Fitting Shop Practical File.

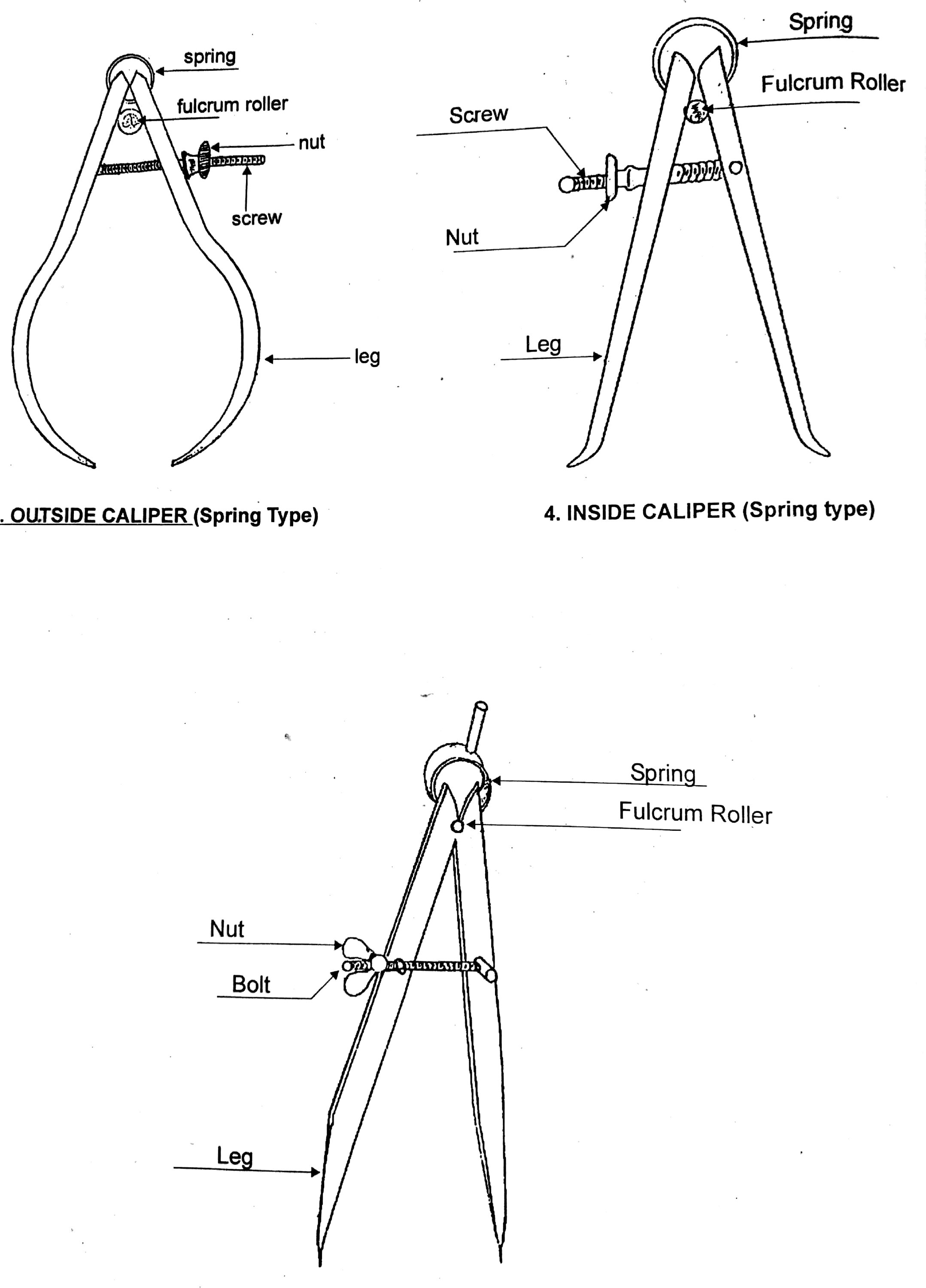

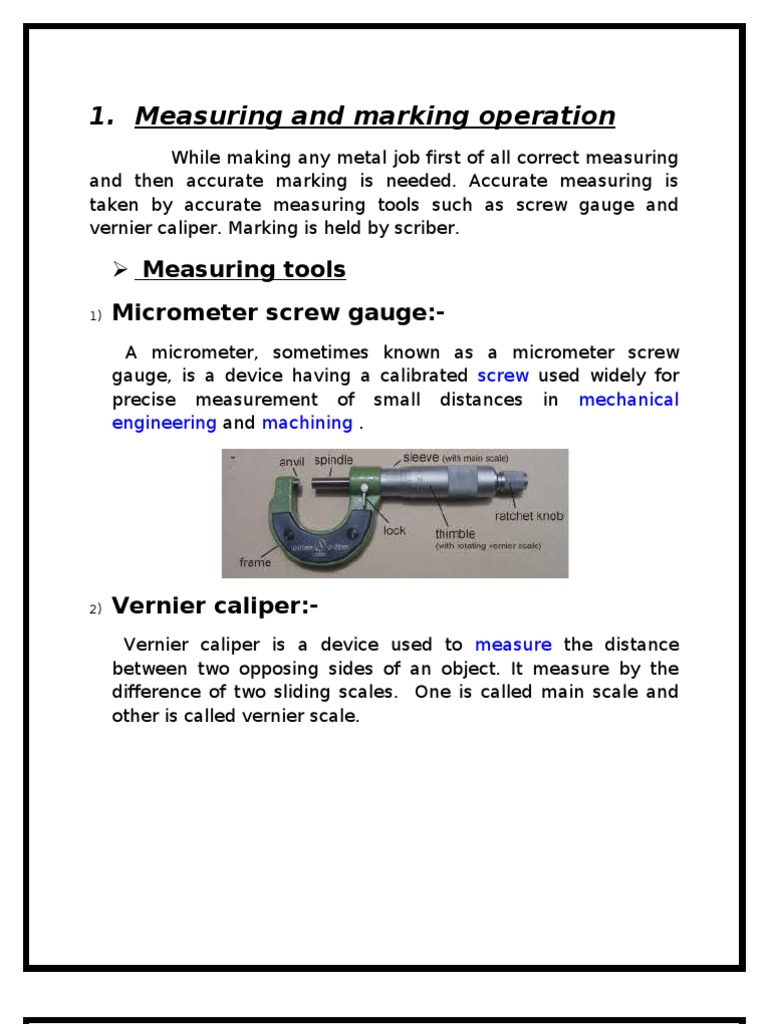

What are the different types of marking and measuring tools used in fitting shop. Other measuring instruments not used in this job Vernier calipers. It is used for checking the straightness and the squareness of a workpiece. It is usually made of carbon steel and parallel ends are grinded.

Name of the Tools used in the Fitting shop Measuring and marking instruments. Vernier height gauge 64. All types of work require the use of large number of tools involving a number of operations such as filing chipping scraping sawing tapping etc.

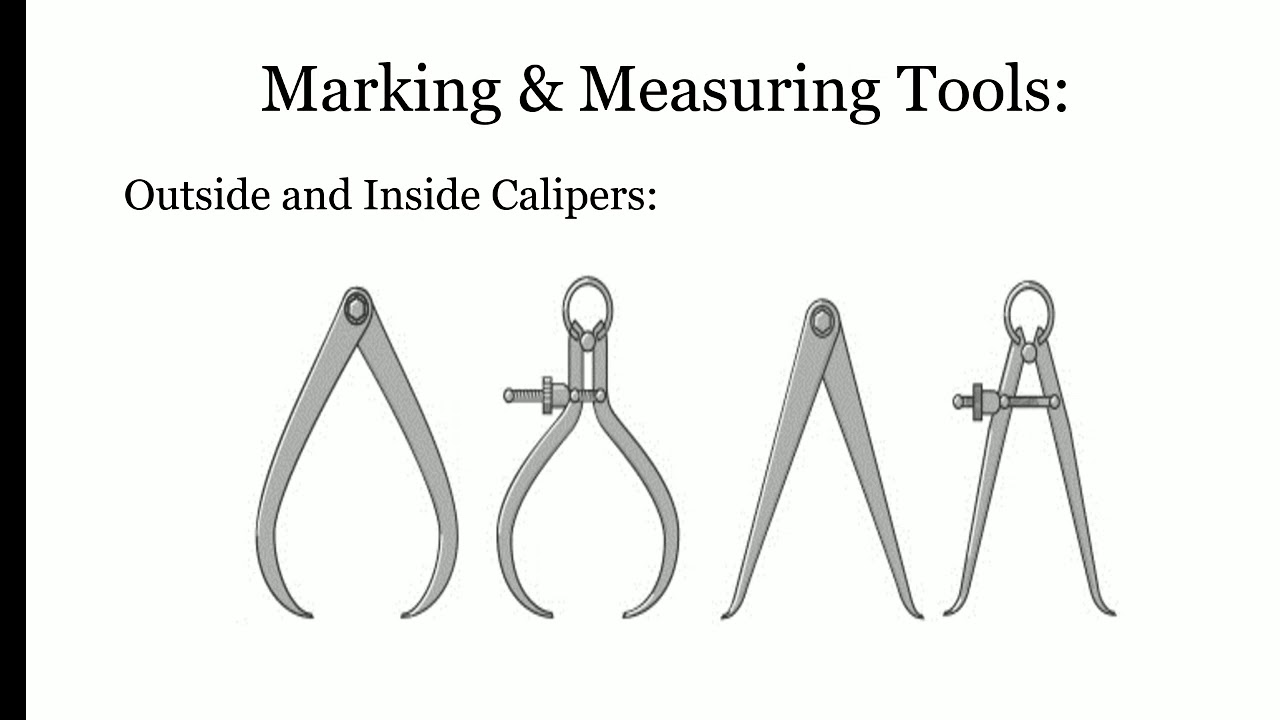

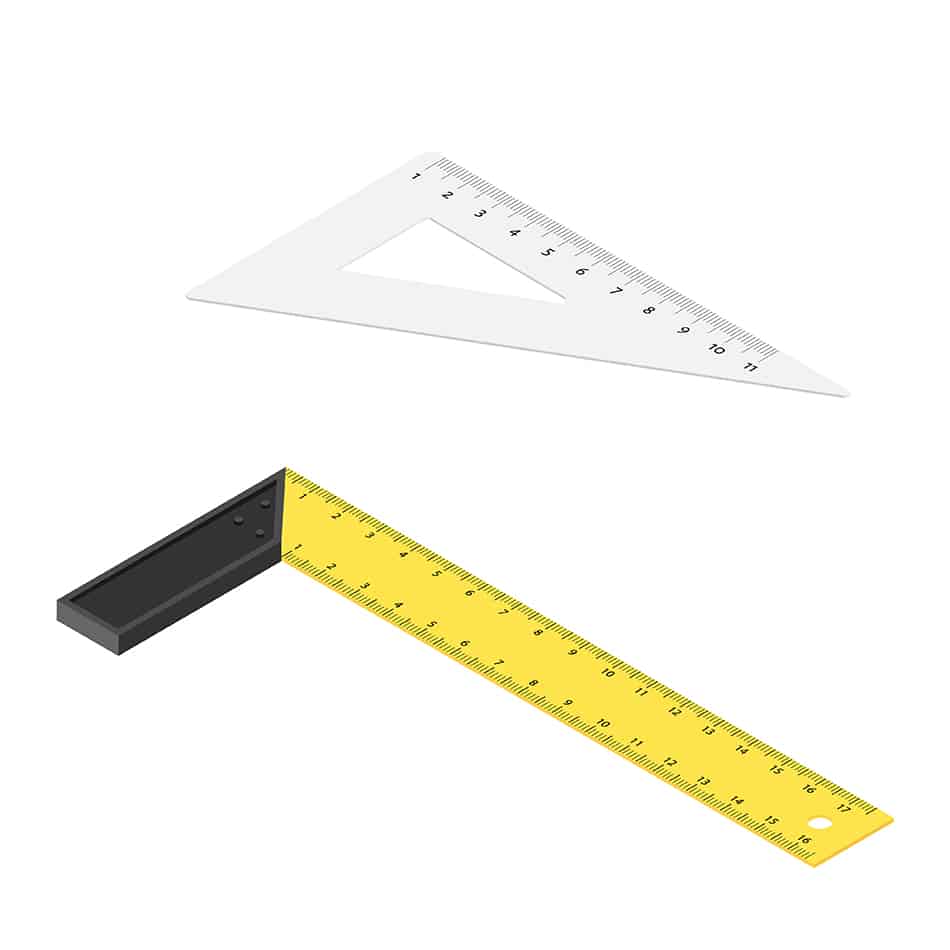

13 MARKING AND MEASURING TOOLS 131 Surface plate The surface plate is machined to fine limits and is used for testing the flatness of the work piece. They are 3 types of Marking tools used in the fitting workshop and are as follows. Engineers Square Engineers square figure 14 is made of hardened tool steel.

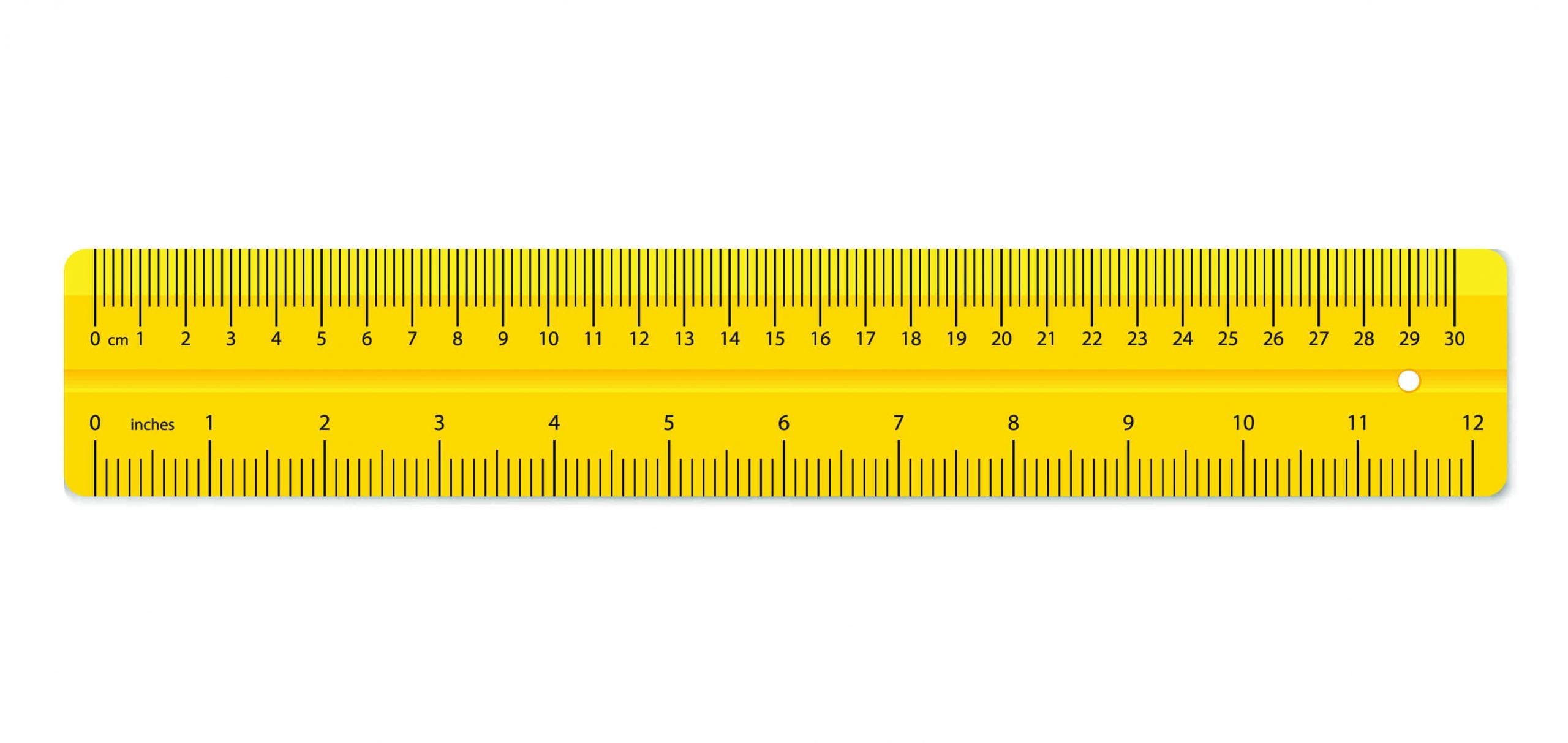

Vernier depth gauge 65. The degree of the finished depends upon whether it is designed for bench work in a fitting shop or for using. A number of marking and measuring instruments namely Rules Try Square Combination Set Bevel Gauge Marking Gauge Mortise Gauge Cutting Gauge Spirit Level Trammel and Compass are commonly used for this purpose.

The striking tool is identified by a hammer. Measuring Tools are used to. A hammer has a heavy iron body with a wooden handle.

The bar of the square slides back and forth to give you different lengths for measuring and marking your boards. The weight range from 025 kg to 2 kg. Use of this marking tool or marking out tools in a fitting shop to mark a given angle with an edge or to check the angular precision of oblique surfaces.