Types Of Holding Tools In Workshop

Common concepts in schools with Holding tools.

Types of holding tools in workshop. At this length a workshop can begin to address ideas and concepts in some depth and teach some skills. Friction-free unlike hammers and lever bars these hydraulic wedges limit any damage to the joints. A4 Machinist vise is a work holding tool for machining activity.

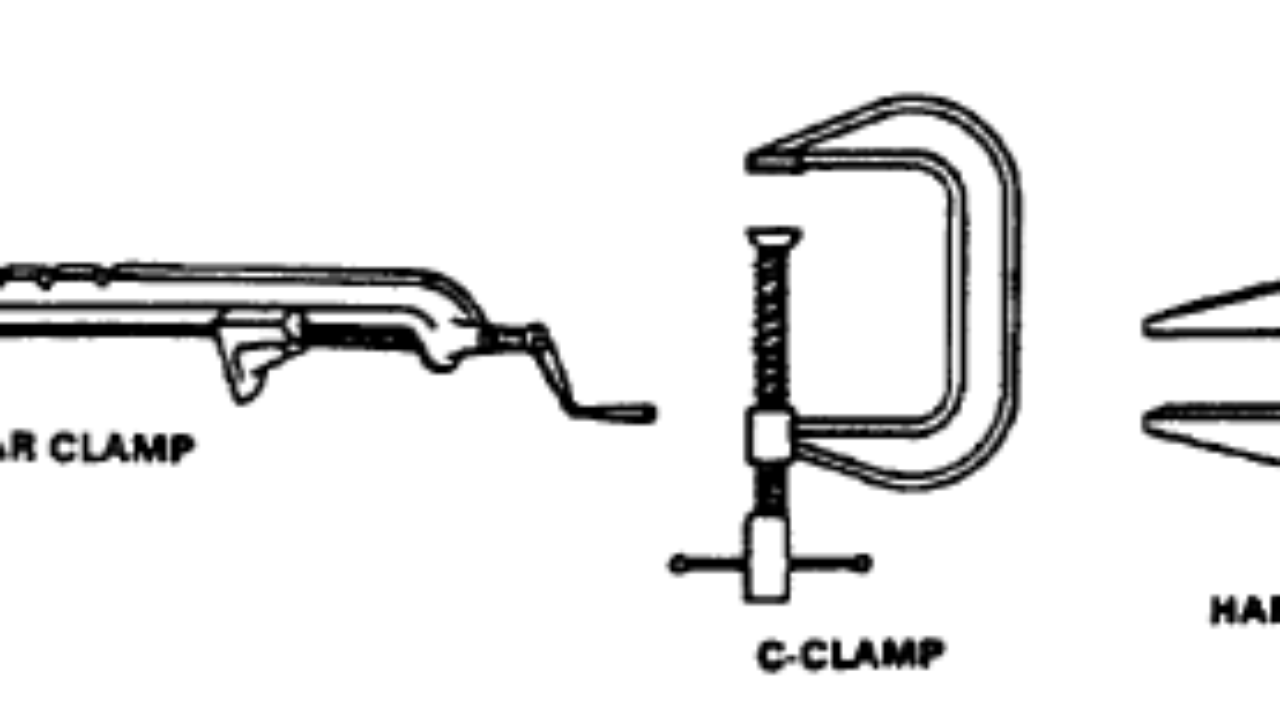

Holding Tools used in Engineering Workshop. There are other similar types of such clamps named as rack clamp screw clamps light duty parallel clamp adjustable bar clamp G or C-clamp and double bar clamp which are useful for holding different sizes and shapes of wooden jobs. Holding tools are also known as Work Holding devices in the Fitting workshop.

Its uses may seem simple limited to drilling holes and inserting screws or fasteners but the drill is backed by a plethora of attachments and drill bits as well as settings for speed power and torque. Hand Vice 5. 90 minutes to 3 hours.

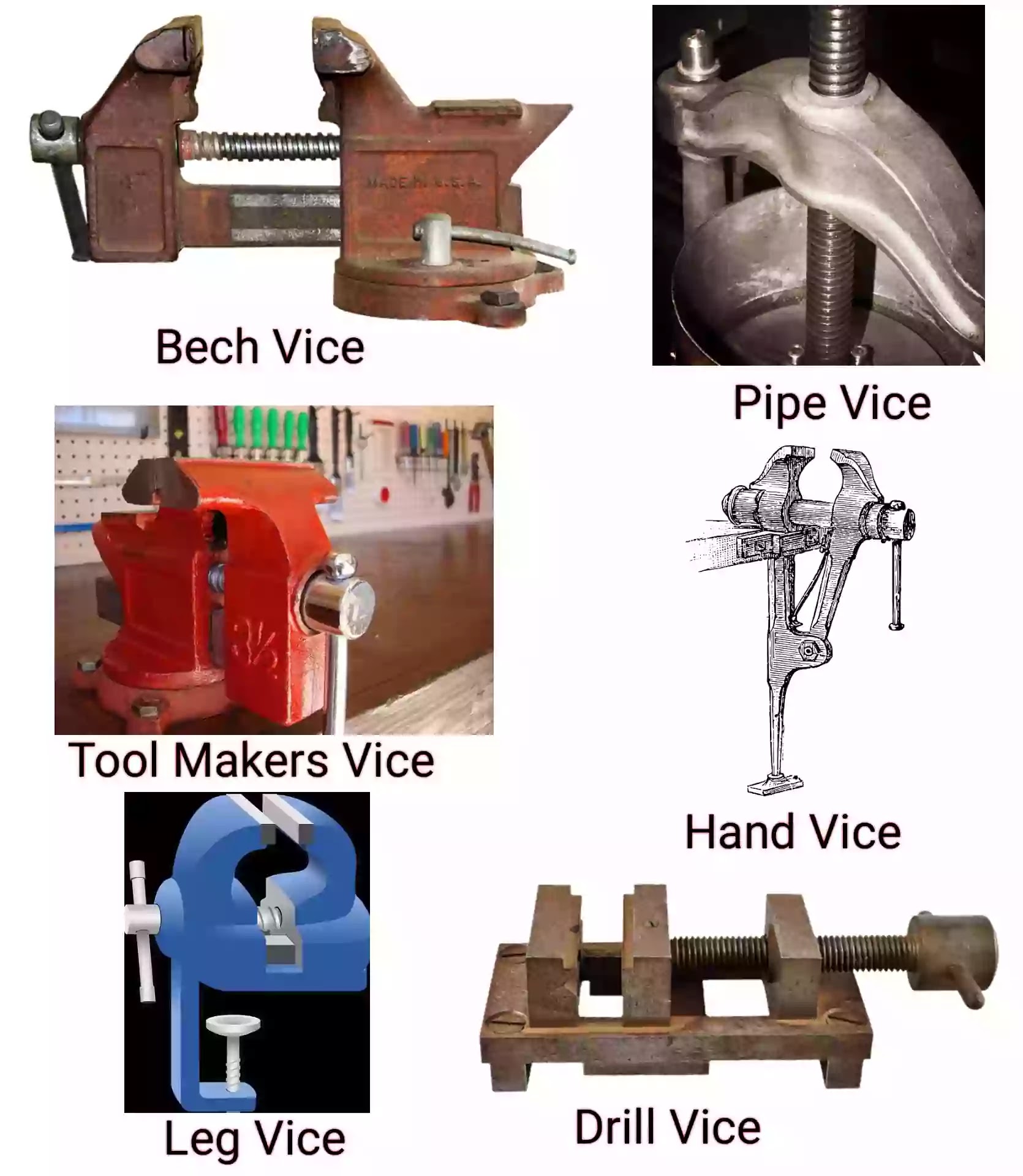

The bench vice is a device commonly used for holding the work pieces. The body of the vice is made of cast iron while the two clamping jaws are made of hardened tool steel. Bench Vice A bench vice figure 20 is the device for holding the workpiece where most hand processes to be carried out.

They are used to hold all types of components between jaws Fixed Jaw and Movable Jaw. They are fixed in a die stock for holding and adjusting the die gap. Tong is used to hold the metal to be forged and must be held securely while working.

A5 Handvise V block with clamp is used to hold metal stocks for small machining operations. Above is a picture that displays an example of me using this tool. The power drill is a very versatile tool used both commercially and on a workshop level.