How To Sharpen Carbide Metal Lathe Tools

When you sharpen a lathe tool bit youre really re-drawing a number of critical angles.

How to sharpen carbide metal lathe tools. For a while now Ive wanted to have a way to sharpen my metal lathe cutting tools. They had several grinders for carbide tools some with face type wheels and one like an ordinary bench grinder with. So in short you can sharpen carbide lathe tools but it takes a little more effort and it wont make them quite as sharp as fresh inserts.

Using a sharp object mark a point roughly 23rds of the way across the top and 12 down the side. Ad At Surplex you will find used machinery and industry equipment at best prices. They require a dimond stone because its the only material hard enough to properly sharpen carbide.

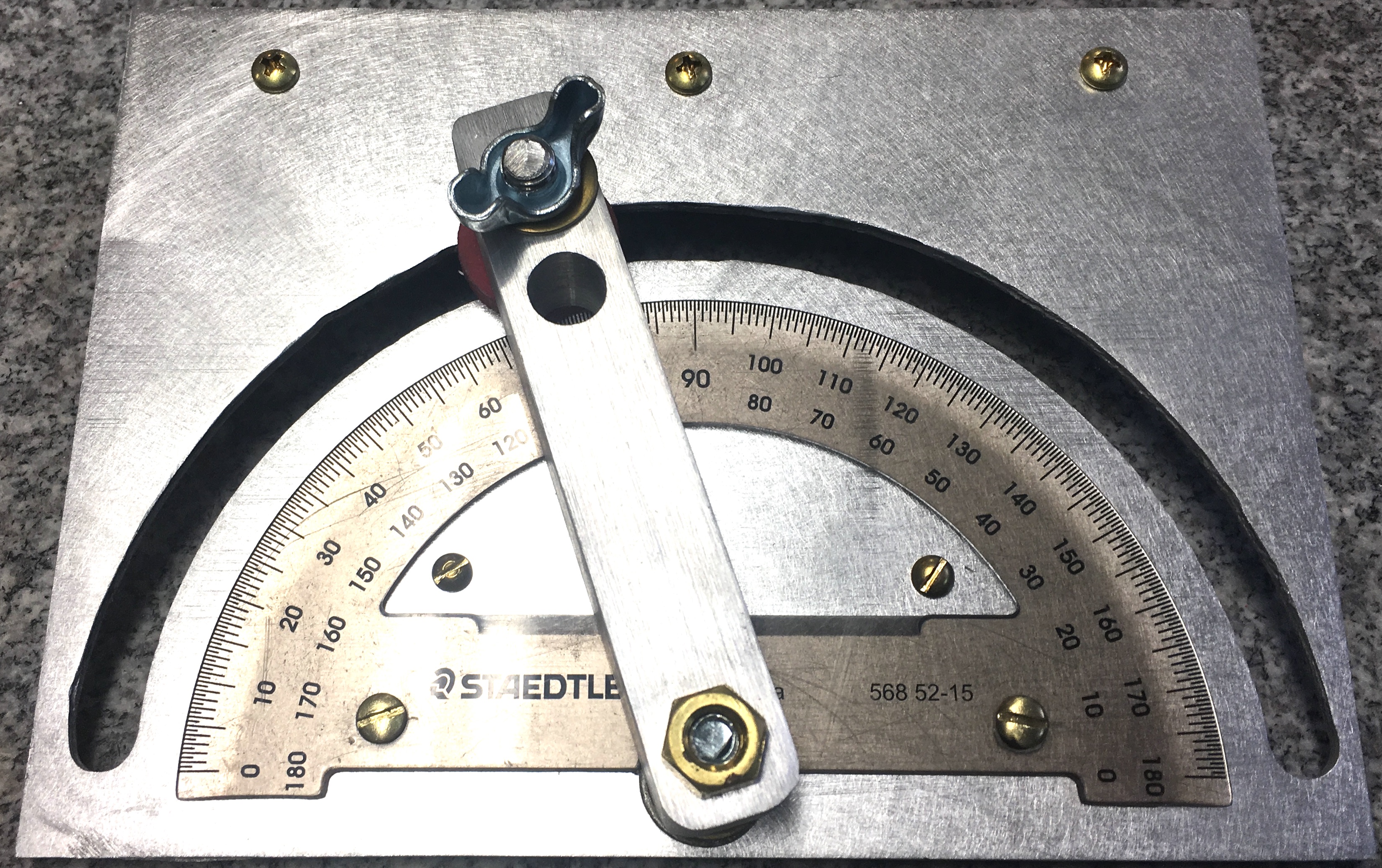

Shown below is what Ive put together to achieve the level of accuracy desired. With steel you can use 10-20 degrees but never try to use a tool ground for steel on brass. It is a sled which rides atop the SVD-110 Tool.

It will grab and possibly rip the stock from the chuck or damage the lathe itself. As I noted in my Sharpening Handbook httpsharpeninghandbookinfo these are not easy to sharpen in a normal manner. In particular the angles must be precise for best cutting action.

It takes a special grinding wheel made of silicon carbide abrasive When I was an apprentice that is all the shop had and we used a lot of brazed on tools in the shop. Be sure to have some lapping fluid on hand to use as a lubricant. Everyone knows that the hardness of cemented carbide is very high.

Lathe tool sharpening is important to making smooth consistent cuts. Apply layout fluid to the top surface and allow it to try completely. Carbide tools can be sharpened on an ordinary bench grinder but it does not do the best job in terms of finish.