How To Setup A Parting Tool On A Lathe

I then cut the end of the blade off to square it off and I cut and ground down the teeth.

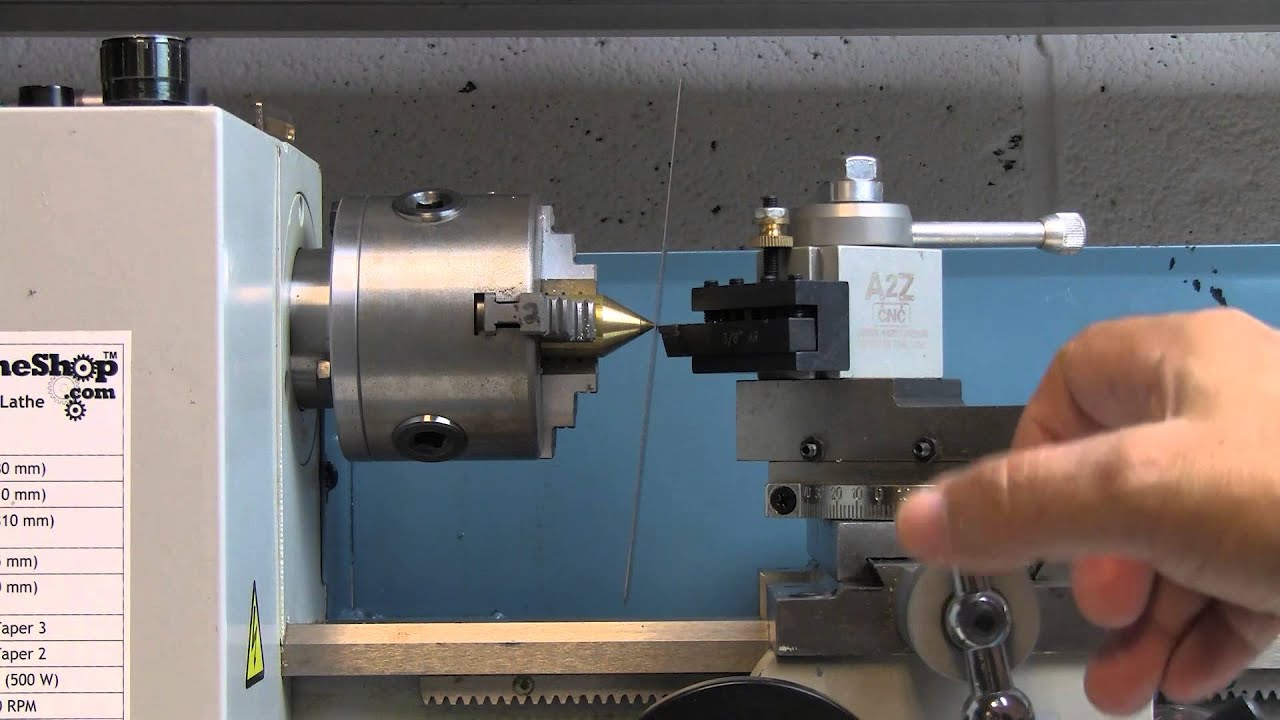

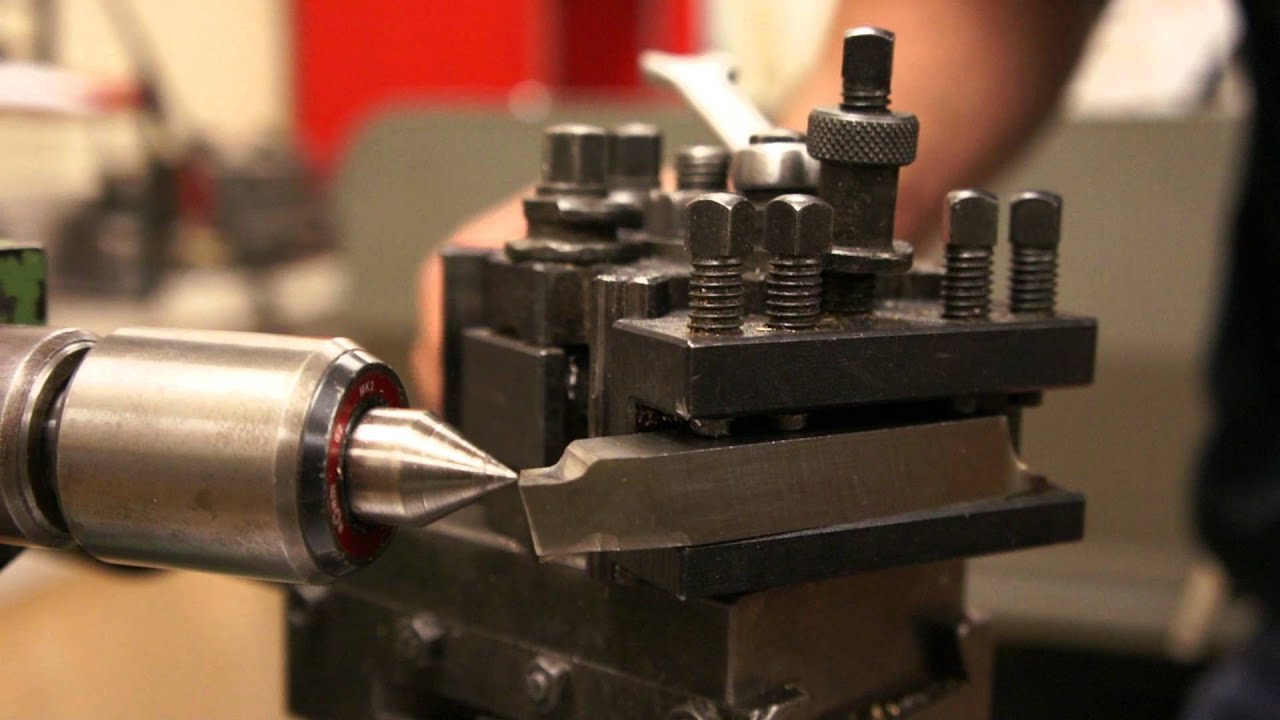

How to setup a parting tool on a lathe. When ground flat on the platform not vertical it will. Install the tool tight in the holder and set the holder perpendicular to the part. First setting proper tool height will minimize the nib.

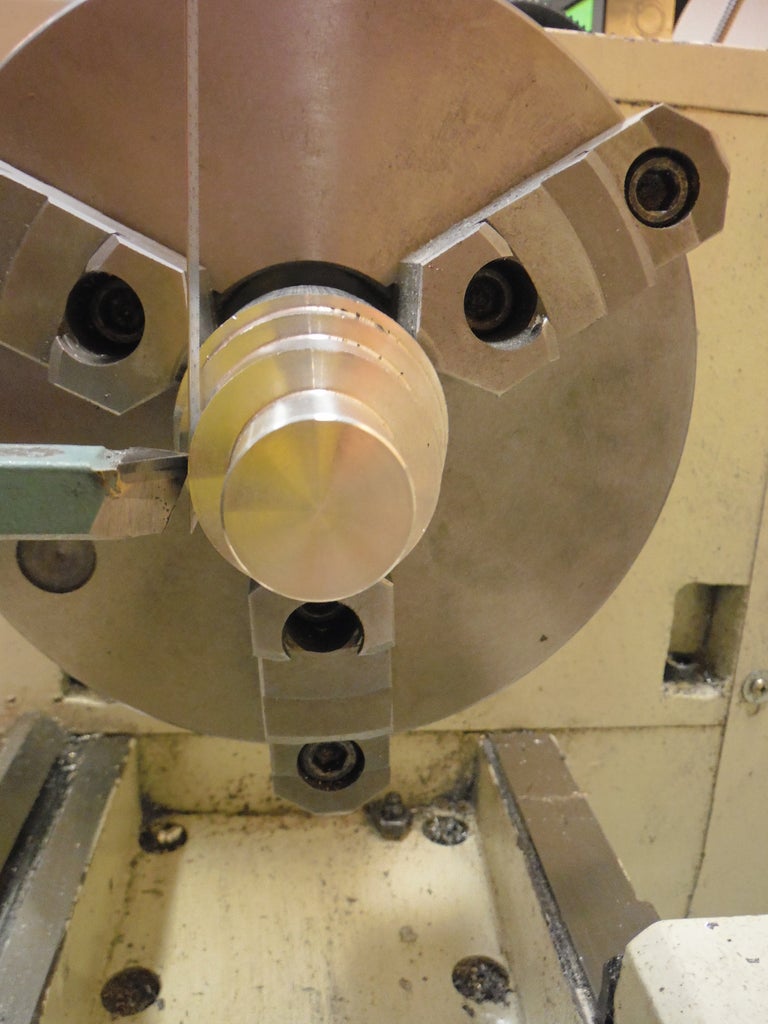

Often enough to avoid having to face it off in a second op. 1 x 26 x 2mm Parting blade. Parting off bowls and lids When turning a bowl on the lathe and holding it by a tenon in a multi-jawed chuck the parting tool can be used to part the bowl from the lathe.

1 x 12mm Parting block suits 26mm blade height. Not a very good shot but it does show the thickness. This video covers how to properly grind the tool how to set the tool so it is ri.

When machining with long overhangs it is especially important to mount the bar correctly to ensure enough clamping contact. Like all tools used on the lathe the part-off tool height must be checked and adjusted so it is as close to the vertical spindle centerline as possible. 2 x 22mm Parting inserts.

1 x Key insert remover. Parting tools are used for parting through spindle stock and several other operations. 45 is a good general angle.

I took a practice cut on some 1 diameter aluminum rod. Next I took the blade over to the disk sander and ground it down to bare metal. Be sure tool is sharp 3.