How To Manage A Cnc Machine Shop

Laurentian sniper1rfa fciron liked this post 05-06-2012 0930 PM 12.

How to manage a cnc machine shop. However a workshop does not need to be messy and will function much better if it is. Individually none of these changes is. Where and how are our CAM files post-processors and NC programs to be managed.

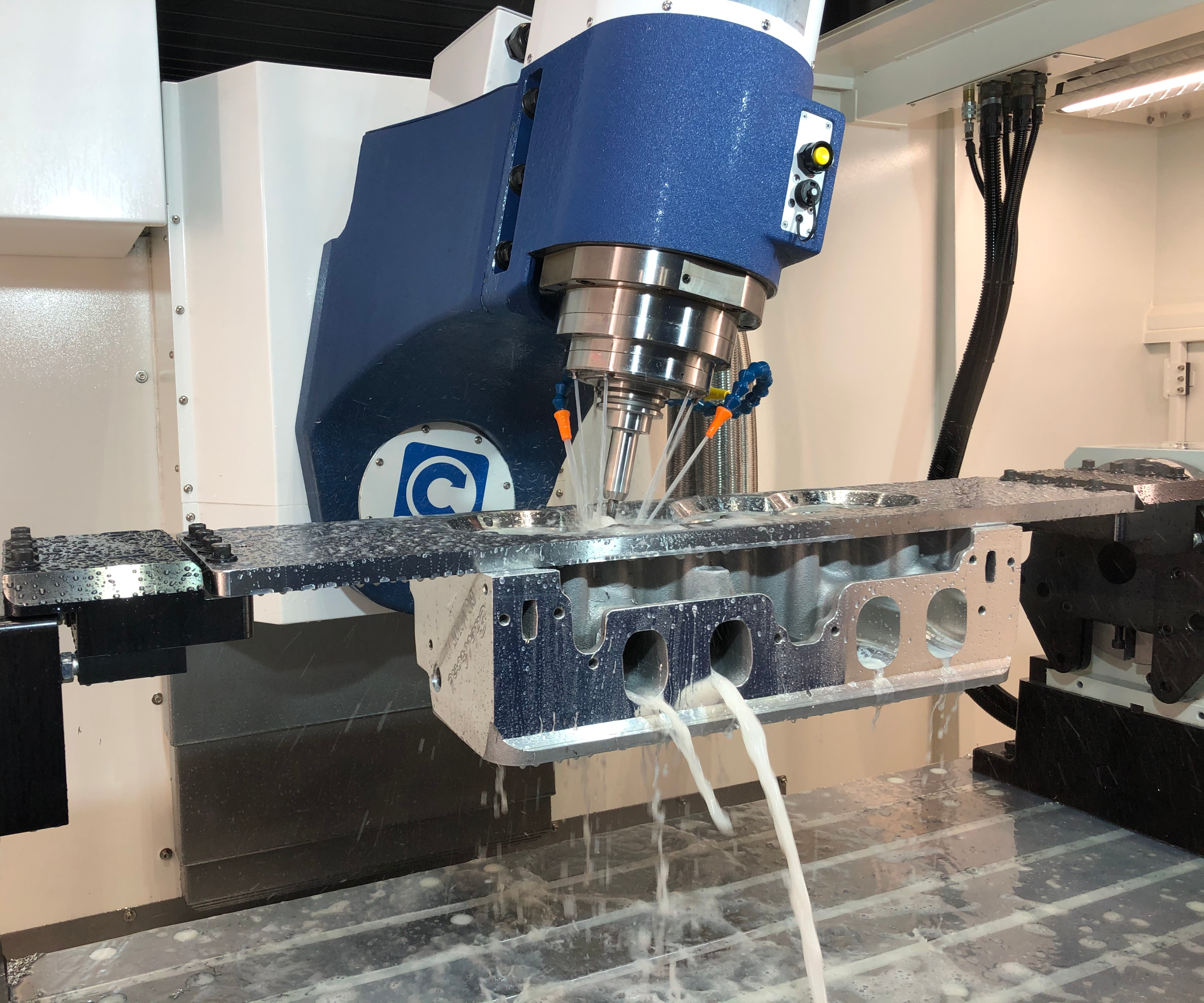

Excellent Benefits and Flexible Schedule. Every person working on a project has his own role and should garner respect from his peers on site. CNC Machining Machine Shop Scraps of wood and metal likely cover the surface of your workshop as proof of how hard you work in that space.

Automotive aerospace medical and. Never allow the use of compressed air for cleaning skin and. Continuous improvement is necessary but managing the rate of change is important.

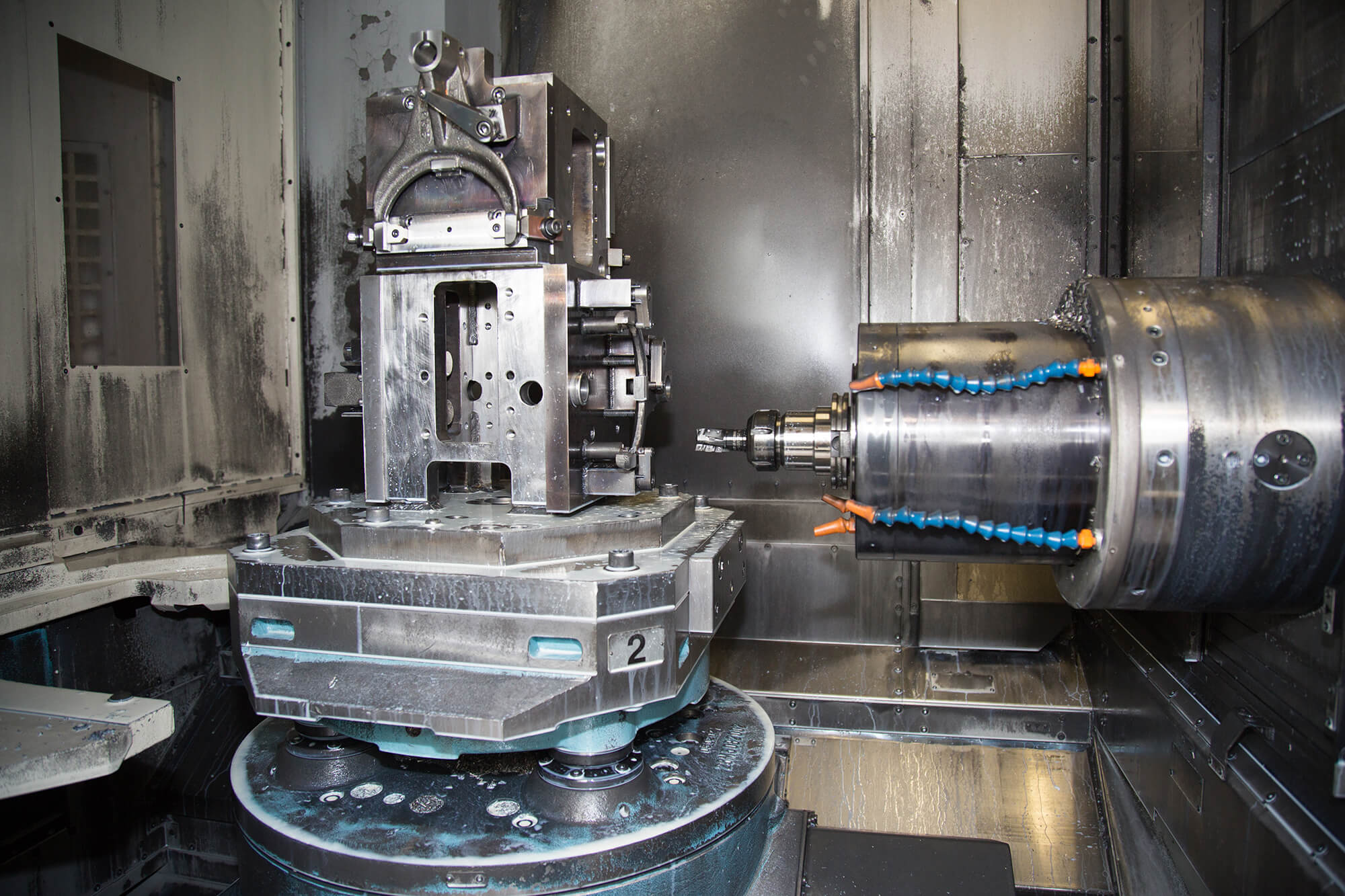

When employees manage the machinery well there is increased production and less wastage. It should go without saying that CNC people directly affect the productivity of the machine or machines on which they work. 75000 - 85000 a year.

Machine Shop Organization Ideas. Depending on the capabilities of the CNC machine shop they can concentrate on specific industries. CNC machine shops.

It may look like a desk job type book but what it teaches fits very nicely with fabrication machine shop work. In machine shops production is critical to revenue. Before the advent of the CNC machine shop all machining equipment was operated manually or mechanically which meant that the accuracy of machined parts depended largely on the skill of the machine.