How To Make Your Own Cnc Wood Router

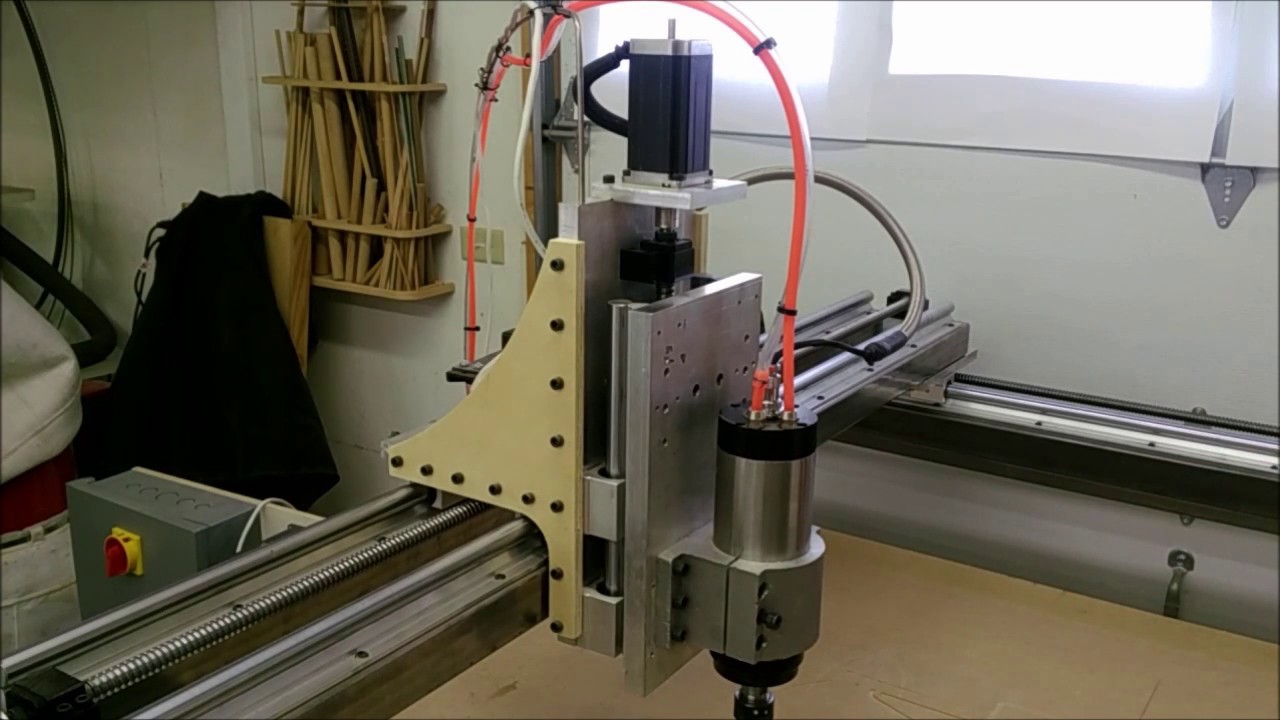

This is how I built myself a CNC router from wood that can even machine metals Support me Patreon.

How to make your own cnc wood router. There are 3 steps to the project Construction Software Manufacture. This is the second DIY CNC Router I made after learning a lot from building the first version. The electronics kit included.

I like to split the shaft hole with a saw kerf which allows the bearing to slide a little more easily. Below is a general outline of how a CNC router works and the steps required to create something using one. This program is a guarantee that in just a couple of hours youll be able to put together your own CNC machine or smart Saw as I like to call it.

Musical instruments have high requirement on precision and aesthetics. But a few students made some simple modifications and improvements. A set of metric and imperial hex keys 316 and 5.

If the machining precision has some gap with the standard it may effect the instruments function. If you are building a 3 axis CNC router you should buy a kit consisting of three sets of linear rails and two linear bearings per rail. Most importantly leverage your new and existing offline connections to get more clients.

Basic digital marketing starting with a social media page is the first step to selling your CNC router business. 3 425 oz-in stepping motors 3 Drivers 30Amp 24-40 Volts 1-164 micro-stepping 1 36v 88a Power Supply 1 Breakout board I wired all the electronics up and added a few more features. With 20 inches wide the kinetic sculpture can run several hours by a single winding.

CNC wood router can make many instruments like piano guitar violin and others. Timing belts rack and pinion and drive screws. By using calipers dial indicators and a machinist square you will need to measure precisely.