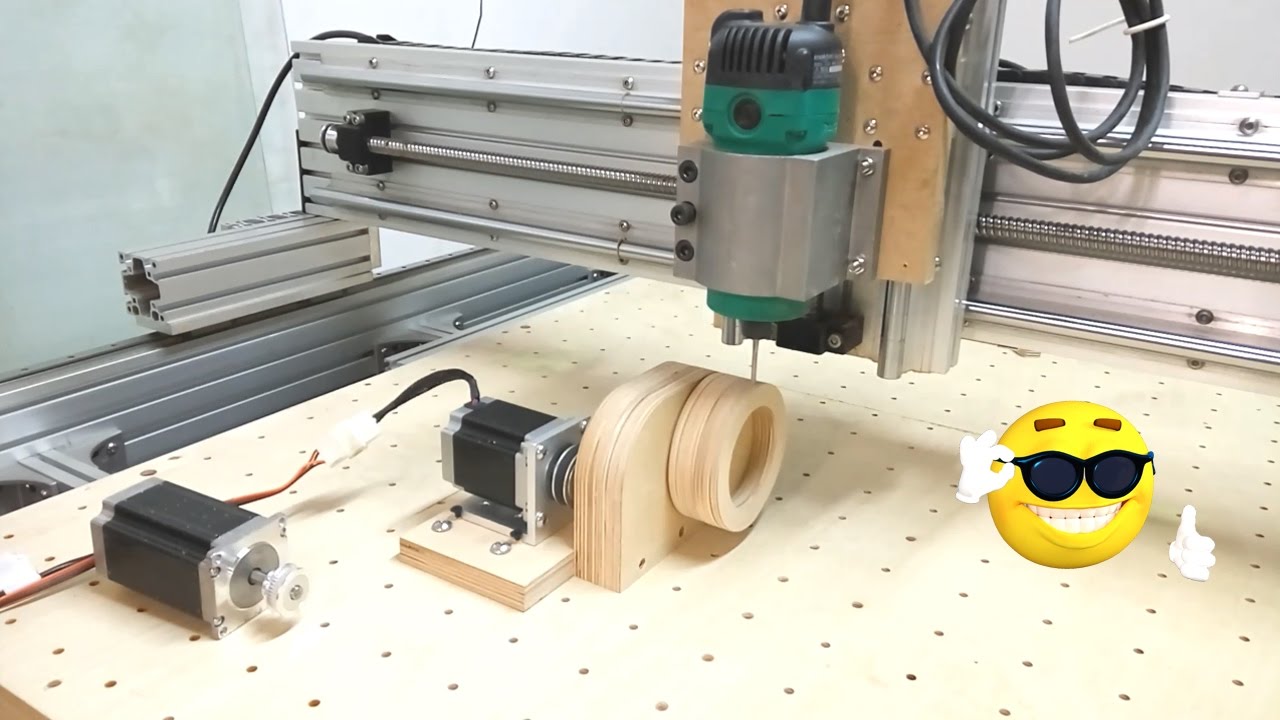

How To Make Lathe Chuck

The faceplate will be permanent so you need to get one specifically for the Longworth chuck.

How to make lathe chuck. This needs to go in fairly precisely. With the new tray on top of the headstock I needed. Just as with the four-jaw chuck screw attachment to attach wood to a lathe using the dedicated screw chuck be sure to seat the blank all the way down to the base for a secure attachment.

If you used a blank to test now make a matching set of four jaws. How to make a 4 jaw lathe chuck using plywoodmichaelpaleyAd cogitandum et agendum homo natus estA chuck is a specialized type of clamp. Then bring up the tail stock to mark the true center.

Of course if you have a CNC metal lathe the whole. Mount your chuck to lathe. One for the 3 jaw and one for the 4 jaw.

As soon as you have the hole done and back of the plate machined to dimensions you mount the backplate on the spindle face it flat and cut the chuck register. It is used to hold a. Screw the studs into the threaded holes and mount the chuck on the lathe.

Now with the bar in the jig tighten the chuck and it should not move. To index the mini chuck so that the slots for the jaws will be at 90 deg I put a brass plug in the chuck blank then screwed in some long 10-32 cap. Now its time to mount your chuck to the lathe after mounting and removing the bowl from the lathe.

Then turn the interior of the bowl. Carefully cutting out the main part on the bandsaw. Mill out the steps on the top side of the jaws.