How To Grind A Lathe Parting Tool

It will have to wait a bit however as the queue is backed up.

How to grind a lathe parting tool. This video covers how to properly grind the tool how to set the tool so it is ri. Inspect the parting tool closely before using. I was working on a handle for a gouge blade.

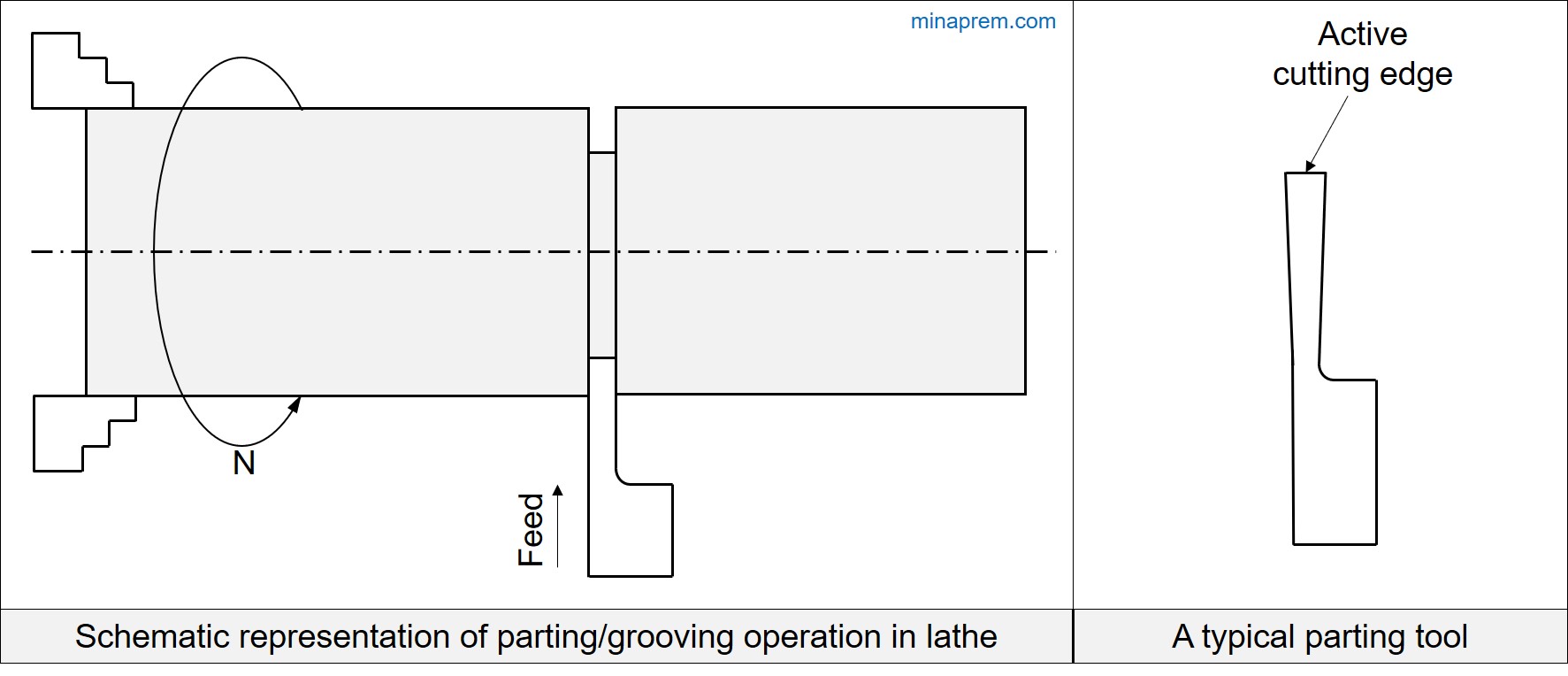

When ground flat on the platform not vertical it will have a flat edge rather than a hollow-grind. Another important step is to make sure the cutting tip of your parting tool is right on the center line of the piece you are parting. 1 Its difficult to sharpen the bevels of a parting tool and arrive at the correct side profile with the ears leading the nose.

If using HSS parting blades grind andor hone the cutting edge to ensure its sharp. Another thought on parting is to try to do your parting as close to the chuck jaws as possible. I then cut the end of the blade off to square it off and I cut and ground down the teeth.

Ad Easy to Use - Laser Fits in Spindle 4-Axis 00002 resolutn Fast Setup. The grinding rest was tipped to give the required side clearance relief and the fence adjusted to give the side cutting edge angle. Im assuming youre talking about your average HSS parting blade including P-type If you grind the top of the blade the tip becomes lower than the original top.

You can see that Ive got a ways to go yet. You can use whatever back rake you like if you achieve it by angling the entire blade like the Aloris holder. To be clear the back rake angle on the P-parallel bits is best controlled by the choice of tool holder.

Using My New Parting Tool. The parting tool has an angle of around 50 degrees. Took it over to the 1 belt sander cleaned up the blade a little more and fine tuned the wood edges.