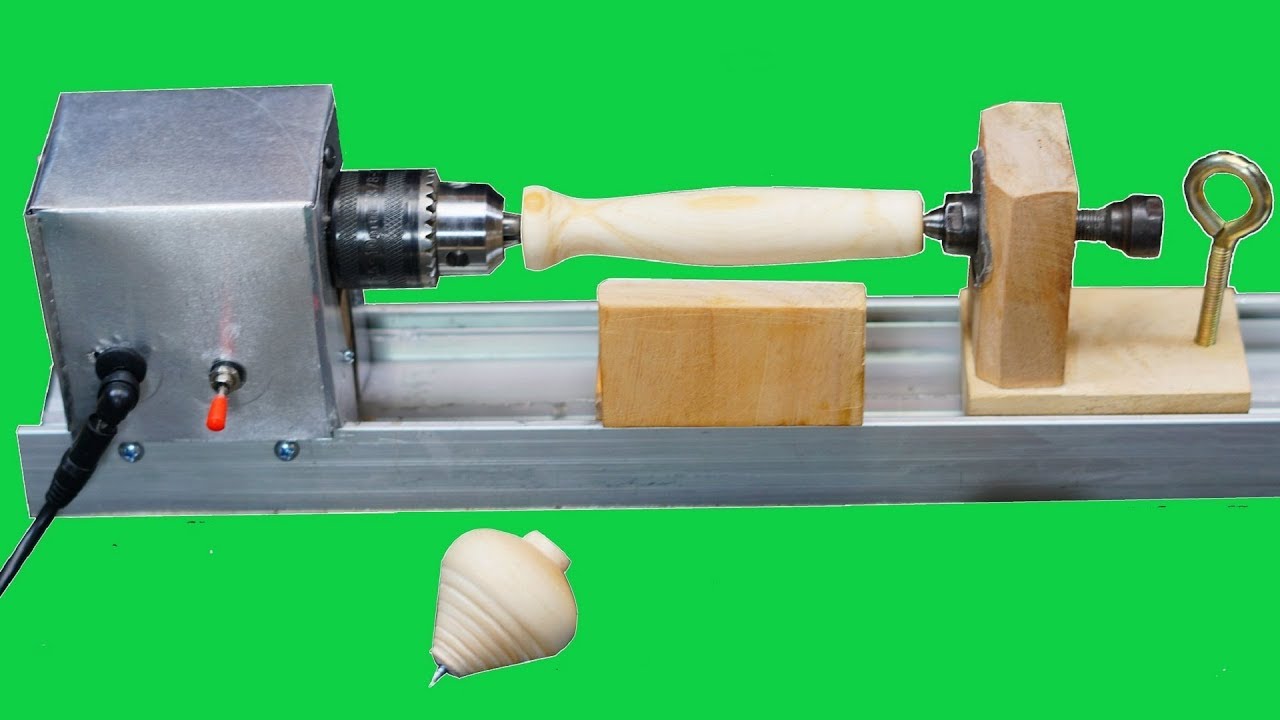

How Do You Use A Wood Turning Lathe

In either configuration if the blank does not seat at the base of the screw chuck it can wobble or work loose and potentially go flying.

How do you use a wood turning lathe. Following are some guidelines to follow when starting any out of round stock. Make sure your lathe is set to its lowest RPM. And a variety of jam-chucks more sacrificial stock.

Woodturning is the process of carving a block of wood into a symmetrical object such as a wood spindle or bowl while using a motor-driven lathe to spin the wood at high speed while cutting tools including a variety of chisels and knives gradually carve the piece into the desired shape. A vacuum system is a great way to hold pieces on the lathe without damaging them. In order to use a wood lathe lock a piece of wood into the head stock and tail stock start the tool at its slowest speed and support the tool with the blad.

The initial turning on the lathe will be safer smoother and easier on you and your lathe. Turn the lathe on making sure it is at the lowest speed setting. Glued to a sacrificial piece of wood which is then screwed to the faceplate.

But the block will not be totally round or balanced. In that case you will use the tried- and-true faceplate likely provided with your lathe and attach your turning stock in a variety of ways. Always Cut With the Grain When woodturning one should always work with the grain.

You want to move in toward it perpendicular to the work piece until the cutting edge just touches the wood. Place the cutting edge of the tool on the rest keeping clear of the rotating work piece check your grip and slowly begin easing it toward the work piece. Another important thing to do is add some lubricant on the bed so that is slides smoothly as you do your woodturning.

Once you have unboxed your lathe first of all put in your spur center and your live center and make sure they meet in the middle on center and that is critical if you do spindle turning. Just as with the four-jaw chuck screw attachment to attach wood to a lathe using the dedicated screw chuck be sure to seat the blank all the way down to the base for a secure attachment. Another useful thing is putting down some W40 or other lubricant on the bed to make it everything slide smoother.