How Do You Make A Sharpening Jig For Wood Turning Tools

May 28 2017 - Woodworking can be a lot of fun but many people get discouraged because they are not knowledgeable enough on the subject and feel that creating nice pieces is a little.

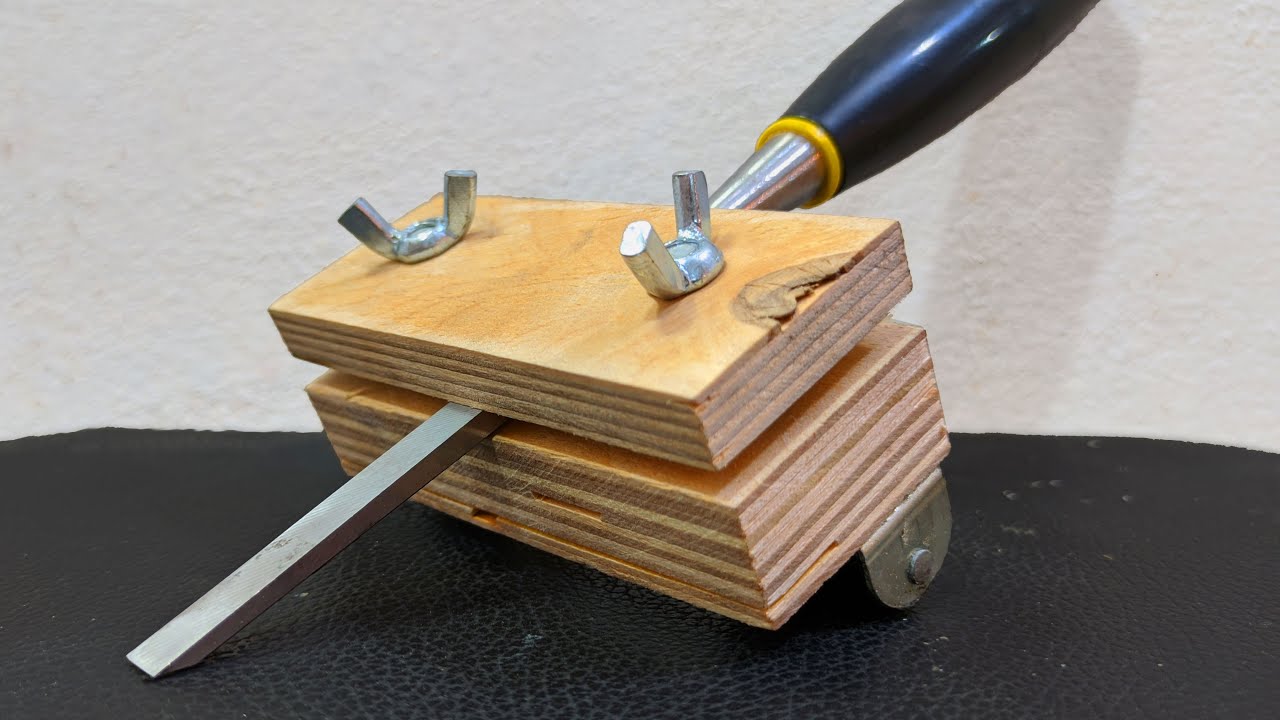

How do you make a sharpening jig for wood turning tools. When actually sharpening gouges with a jig or completing a new grind set the tool in the jig using the templates. To sharpen adjust the flat tool rest so that the tools bevel angle matches the wheel. Just ignore those bits in the middle I then bolted the Grinder to the top board centered it as best I could.

Pivot the tool back and forth over the moving wheel. You want to remove that debris and prepare your grinder for the optimum sharpening of your lathe tool. With the end of the holder in the jig arm adjust the arm until the tool meets the wheel at 45 degrees.

To use the jig for an Oland Tool. If you do it yourself allow some extra length for the 30mm square and angle due to the cutting blade thickness. You can either have the supplier cut the steel or do it yourself.

Focus on removing an equal amount from both faces so that the point remains centered on the tool. Chisels gouges bowl gouges spindle gouges carving tools woodturning scrapers parting tools block plane irons and more. Compare Pricing Distributors Save.

Turn the grinder on and lower the tip of the parting tool onto the moving grinding wheel for a few seconds. This is a sharpening system that comes with everything you need to sharpen your turning tools. It comes with all the angle set-up jigs and fixtures you need.

The end result should be the point of the parting tool be ground to a sharp squared of point. Learn the basics woodturning tool sharpening techniques. What you need to get started sharpening lathe turn.